Automotive repair shops are bustling hubs of activity, where skilled mechanics and technicians work tirelessly to keep our vehicles running smoothly. In the midst of these grease-stained floors and whirring tools, one crucial element often takes a backseat – fresh air exchange. The quality of air in an automotive repair shop is vital for the well-being of both workers and customers, and it directly affects the efficiency and safety of operations. In this blog post, we will explore the significance of removing dangerous exhaust fumes, replacing them with fresh air, and recovering the heat using Energy Recovery Ventilators (ERV).

The Dangers of Stale Air

Automotive repair shops are notorious for the presence of harmful exhaust fumes generated by vehicles under repair. Carbon monoxide (CO), volatile organic compounds (VOCs), and various other noxious emissions can accumulate indoors if not properly managed. Inhaling these pollutants can lead to a range of health issues, including headaches, dizziness, and more severe respiratory problems over time. Ensuring the removal of dangerous exhaust fumes is, therefore, paramount.

Fresh Air for Improved Productivity

Stale air in a repair shop isn’t just harmful; it also negatively impacts productivity. Poor indoor air quality can lead to worker fatigue, decreased concentration, and irritability. All of these factors can have a direct impact on the quality of repairs and, consequently, customer satisfaction. By maintaining a continuous supply of fresh air, repair shop owners can create a healthier and more comfortable working environment, boosting their staff’s productivity and morale.

The Role of Energy Recovery Ventilators (ERVs)

One of the most efficient ways to achieve optimal air quality in an automotive repair shop is by employing Energy Recovery Ventilators (ERVs). ERVs are advanced ventilation systems designed to remove stale air, bring in fresh air, and recover the heat energy from the outgoing air. Here’s how they work:

1. Exhaust Air Removal: ERVs remove the contaminated air containing exhaust fumes and VOCs from the shop.

2. Fresh Air Supply: Simultaneously, ERVs introduce fresh outdoor air into the workspace. This process ensures a constant supply of clean air, maintaining a healthier environment.

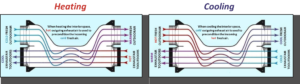

3. Heat Recovery: ERVs are equipped with heat exchangers that transfer heat from the outgoing air to the incoming fresh air. This energy recovery not only saves money on heating and cooling but also ensures a comfortable temperature inside the shop.

Benefits of ERVs in Repair Shops

1. Safety First: ERVs help in efficiently removing hazardous exhaust fumes, reducing health risks for workers and customers alike.

2. Improved Air Quality: ERVs ensure a continuous supply of fresh air, preventing the accumulation of pollutants that can lead to health problems.

3. Energy Efficiency: ERVs help in maintaining a comfortable indoor temperature without overburdening HVAC systems, resulting in significant energy savings.

4. Enhanced Productivity: Clean and fresh air can contribute to a more focused and energetic workforce, ultimately leading to improved repair quality and customer satisfaction.

Conclusion

In automotive repair shops, fresh air exchange is not a luxury; it’s a necessity for the well-being of employees and the efficiency of operations. Installing Energy Recovery Ventilators (ERVs) is a prudent investment, as it not only removes dangerous exhaust fumes but also ensures a constant supply of clean air while recovering heat energy. By prioritizing air quality, repair shop owners can create a safer, more productive, and cost-efficient work environment, benefiting everyone involved in the process.

Through decades of experience, we have found the most efficient air exchangers in the industry. Call today to discuss your application.